Ecoloc ESD Constat

For areas where electrostatic discharge is an everyday threat, patented Ecoloc ESD (Electro Static Dissipative) tiles are specifically designed and manufactured to prevent damage to electrical devices and maintain safety for employees.

Enquiry for Ecoloc ESD Constat

Ecoloc ESD flooring offers safety in work environments where electrostatic electricity is a hazard to both machinery and employees. Specially designed for areas at risk of static and electrical surges such as laboratories, computer suites and electronic assembly lines, Ecoloc's patented ESD tiles are the only interlocking tiles that are tested to meet all EU regulations.

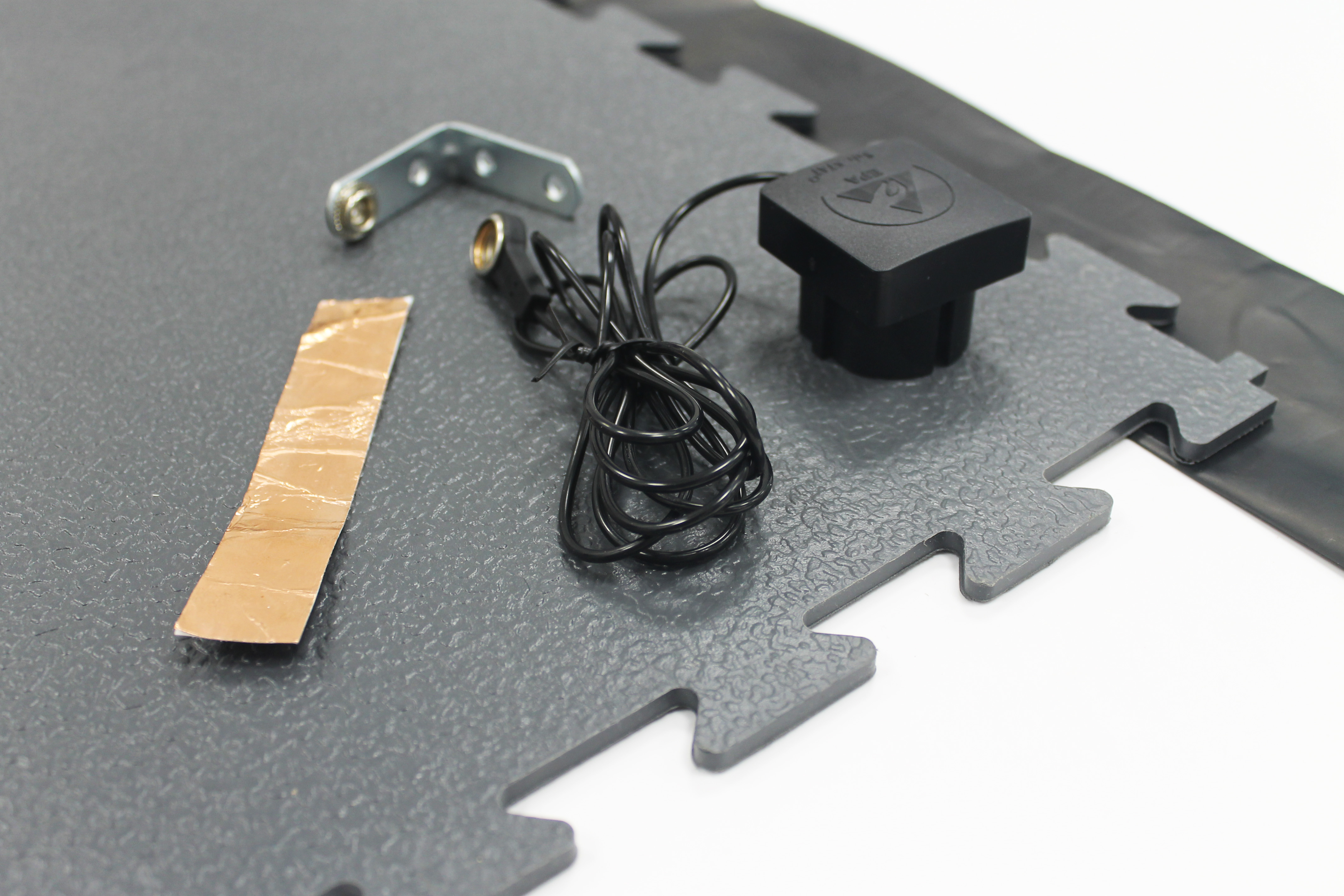

ESD flooring can be used as the primary grounding mechanism for the establishment of an electrostatic protective area (EPA) in your factory, warehouse or office. The ESD kit consists of a grounding tile, plug, connector and conductive tape that inhibits static generation, preventing potentially damaging and costly electrostatic surges.

Staining Resistance- Yes

Castor Chair Suitability- Yes

Squareness & Straightness- <0.05

Abrasion Resistance (Wear Group)- T

Class 34- Commercial/Very Heavy- Yes

Class 43- Light Industrial/ Very Heavy- Yes

Flexibility- No cracking at 10mm

B02 Light Fastness >7

Residual Indentation (mm)- ≤0.10

Impact Noise Reduction (Db)- 16

Dimensional Stability (%)- 0.11

Curling After Exposure Heat (mm)- 0.15

European Building Standard- Yes

Reaction to Fire Performance- Bfl-S1

Formmaldehyde Content (Class)- E1 (CWFT)

Thermal Resistance (m2 F/W)- 0.03807

Electrical Resistance (Ohms)- ≤105-7Ω

Static Electrical Propensity (Kv)- <2.0

Slip Resistance (Class)- DS

German Standard Slip Resistance- R10

Mechanical Resistance- 17N/mm2

Reach Compliant- Yes

Hardness- 92

Benefits and technical features of this product are :

Easy installation

Low maintenance

Anti-slip

100% recyclable

Sound absorbing

Anti-fatique

Resists punctures & abrasions

Available in dark grey and black

At low temperatures, it is recommended to let the tiles acclimatize for a minimum of 12 hours before installation. Installation is best carried out at temperatures between 18 and 25 degrees.

Day to day cleaning using a damp mop or rotary scrubber dryer.